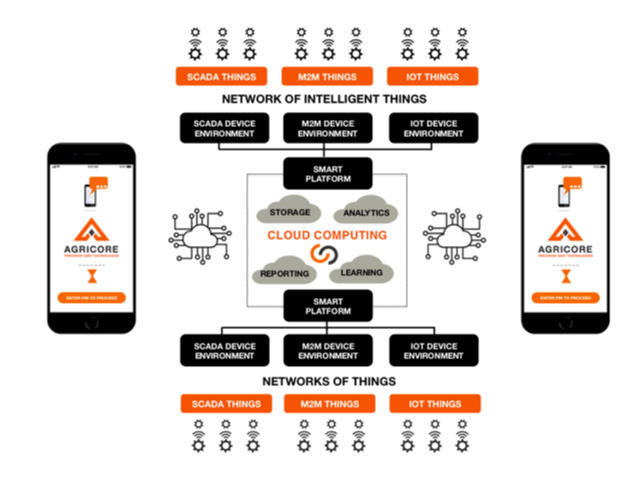

The modular nature of the Smart Platform and all the Agricore solutions will also allow farmers to add and combine other capabilities in time, all on the same platform. This includes the monitoring and control of pumps and irrigation systems, electrical systems, moisture levels, livestock monitoring, generators and other forms of asset management, and various other elements supporting the transition to Smart Farming and Smart Supply Chains (upstream and downstream).

All of this serves to minimise the risk of running out of food and to significantly reduce the cost of carrying excessive stock with losses of feed at the end of growth cycles. At the same time it significantly improves the balancing of capacity at fleet management level and the scheduling of deliveries for feed distributors, creating further supply chain efficiencies.

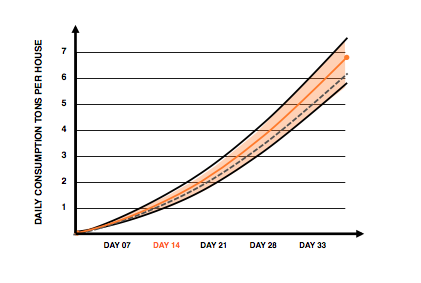

EXAMPLE TWO

Algorithms to automatically calculate how many tons of feed need to go into individual silos during actual delivery and load stage.The algorithm allows the farmer to decide on a re-order threshold, takes into account silo capacities and the predicted fill level at the time of filling. It then calculates when the next delivery will be needed, how much to order, as well as how many tons of feed need to go into individual silos on the farm. Effectively this reduces systemic risk for the industry.

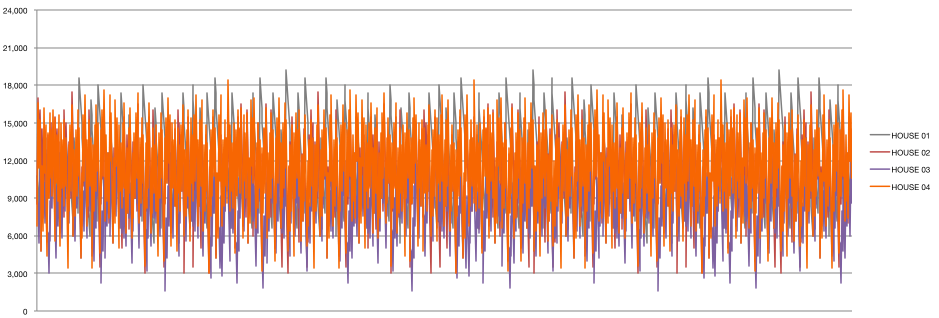

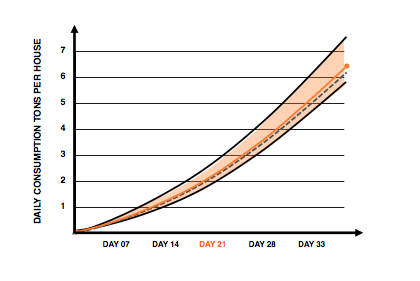

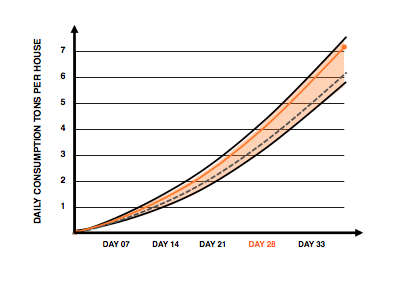

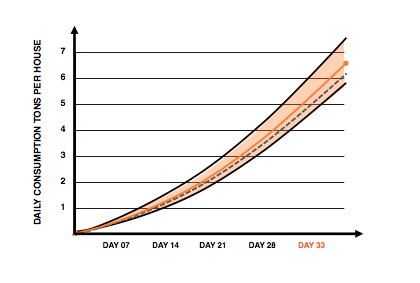

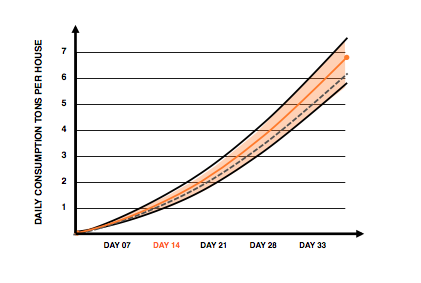

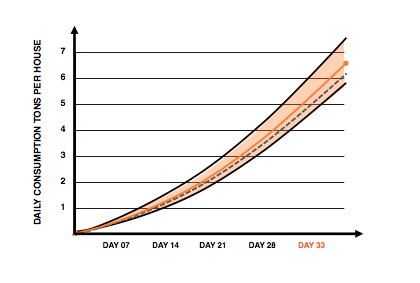

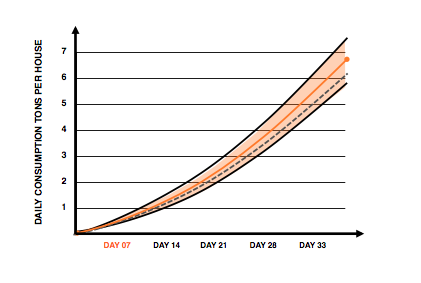

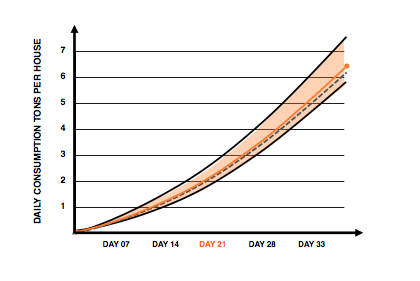

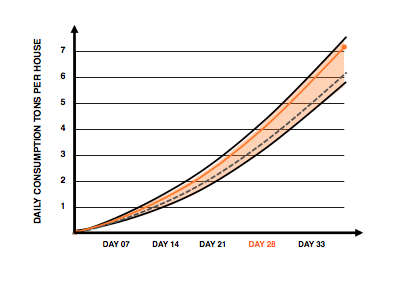

The graph below provides an example of dynamically managed silo levels for four chicken houses, with different breeds of layer hens, significantly different numbers of hens placed, and real time adjusted for mortalities and changing feed consumption rates over a three year period. The algorithm automatically assigns a specific number of truck segments (tons) to each silo for each delivery.

The information provides farmers with the information they need to apply different quantities of different stages and feed types to different houses, relative to the actual growth and consumption rates measured. Critically this also provides the farmer with information about how much feed to order until the end of the cycle, without resulting in excessive amounts of feed at the end of the cycle.

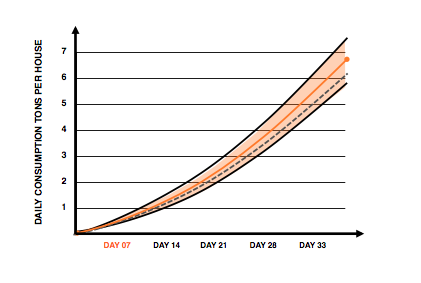

Please note that the movement of the curves are exaggerated for purposes of demonstration on the website.

The Smart Platform is a multi-tenant environment that was developed for monitoring and controlling a large number of in-field devices and multiple options for device to server communication layers. This provides a highly suitable environment for the development of agricultural applications.

Combined with data analytics and integrating external sources of ecosystem information, such as precipitation, space observation data for tracking changes in vegetation or other elements over time, this provides a very powerful environment for enabling farming automation and yield management.

Agricore has initiated a project to leverage its existing technologies to develop solutions for monitoring farming operations. While we already have most of the technology available, specific solutions are in various stages of development.

EXAMPLE ONE

Algorithms to dynamically adjust projected feed consumtion rates for individual chicken grower and layer houses. This is based on various aspects such as placement weights, age, mortalities, weight at different growth stages, catching schedules, and several more elements.

Sensor measurements also serve as continuous dynamic validation of individual runrates and expected consumption for each chichen house, whether for grower or layer houses.